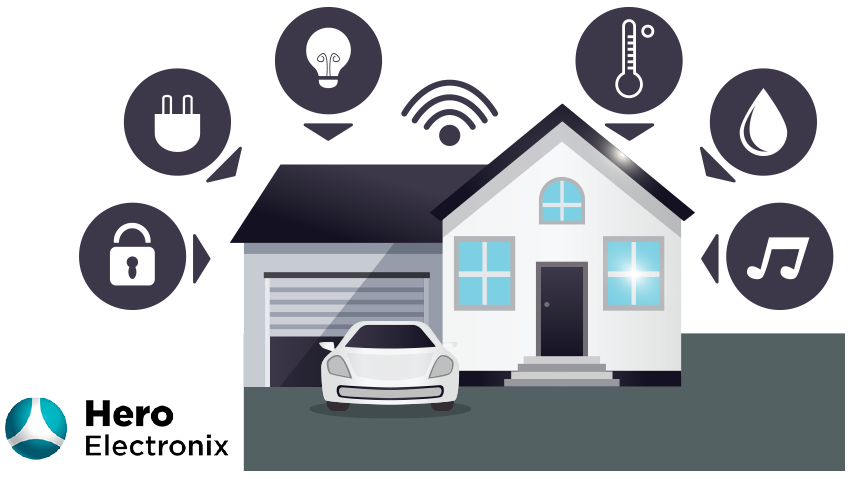

The home automation market is growing at an unprecedented pace, especially in the urban parts of India. Many well-known real-estate developers are now providing homes to its customers with cutting-edge technologies being the core USP [Unique Selling Point]. The demand for smart-homes is largely being driven by the increased concerns about safety, privacy & security in the urban parts in India.

As per a report titled ‘India Home Automation Market by Product Type, Technology, and End-User: Opportunity Analysis and Industry Forecast, 2019-2026’, the Indian home-automation market is expected to reach $13,574.1 million by 2026, growing at a CAGR of 29.8% during the period 2019~2016 [Source].

Growing mobile internet penetration, competition between different ISPs [Internet Service Providers], growing disposable income, improved lifestyle, and increased awareness about the advantages of home automation are some of the major drivers behind the growth of home automation in India. Smart lighting systems, smart bulbs, smart cameras, and other avenues related to smart-homes are expected to fuel the growth of the segment.

For the young generation, smart homes are no longer a differentiated offering but essential components of the dwelling specifications. When it comes to converting an existing home into a smart home, there are a lot of doubts in the minds of the users. Some of the pertinent questions are:

- Will there be any re-wiring for fitting the smart-home essentials?

- What if there is no internet connectivity? Can I fall-back to the older system for operating the connected devices?

- What will be the AMC [Annual Maintenance Contract] charges?

Easy Homes by Schneider Electric

Keeping these and a number of other questions that arise in the mind of the customers, Schneider Electric, the global leader in digital transformation of energy management and automation announced the launch of Easy Homes – one of their innovations in the Smart Home space in December 2019. There were a number of technology bloggers and tech journalists present at the launch event in Bengaluru.

I could not blog about the event in December due to personal & professional commitments after I moved into full-time writing in the month of November 2019. To maintain the same motivation in blogging is one of my new year resolutions of 2020 :). Let’s get back to the launch by Schneider Electric.

Easy Homes by Schneider Electric is one of their innovations in the Smart Home space. Bringing IoT to power homes, Schneider Electric’s Easy Homes empowers customers to manage power in their homes through a single app.

Easy Homes – The ‘Smart’ Integration

With four interfaces, it can be operated by everyone through Alexa or Google Home, smartphone, remote and switches to control power usage in the house. Designed to meet the unique requirements of everyone, it converts homes into a smart home, turning every switch and appliance into a connected device.

While most of the smart home solutions are designed to be installed in new homes, existing homes and retrofit projects need to be made smart. Schneider Electric believes that it is imperative to design smart home solutions for Indian customers comprising families with people across generations – from millennials to parents and grandparents.

Speaking about the solution, Srinivas Shanbhogue, Vice President, Retail Business, Schneider Electric India, said

At Schneider Electric, we are committed to providing ease of access to the new age customers through energy-efficient smart home solutions. Apart from ensuring energy efficiency, smart home solutions should be easy to install and operate thereby making life easy for individuals navigating small struggles of managing electricity touchpoints in the home seamlessly. We understand that the #StruggleIsReal and with Easy Homes, we hope to address these.

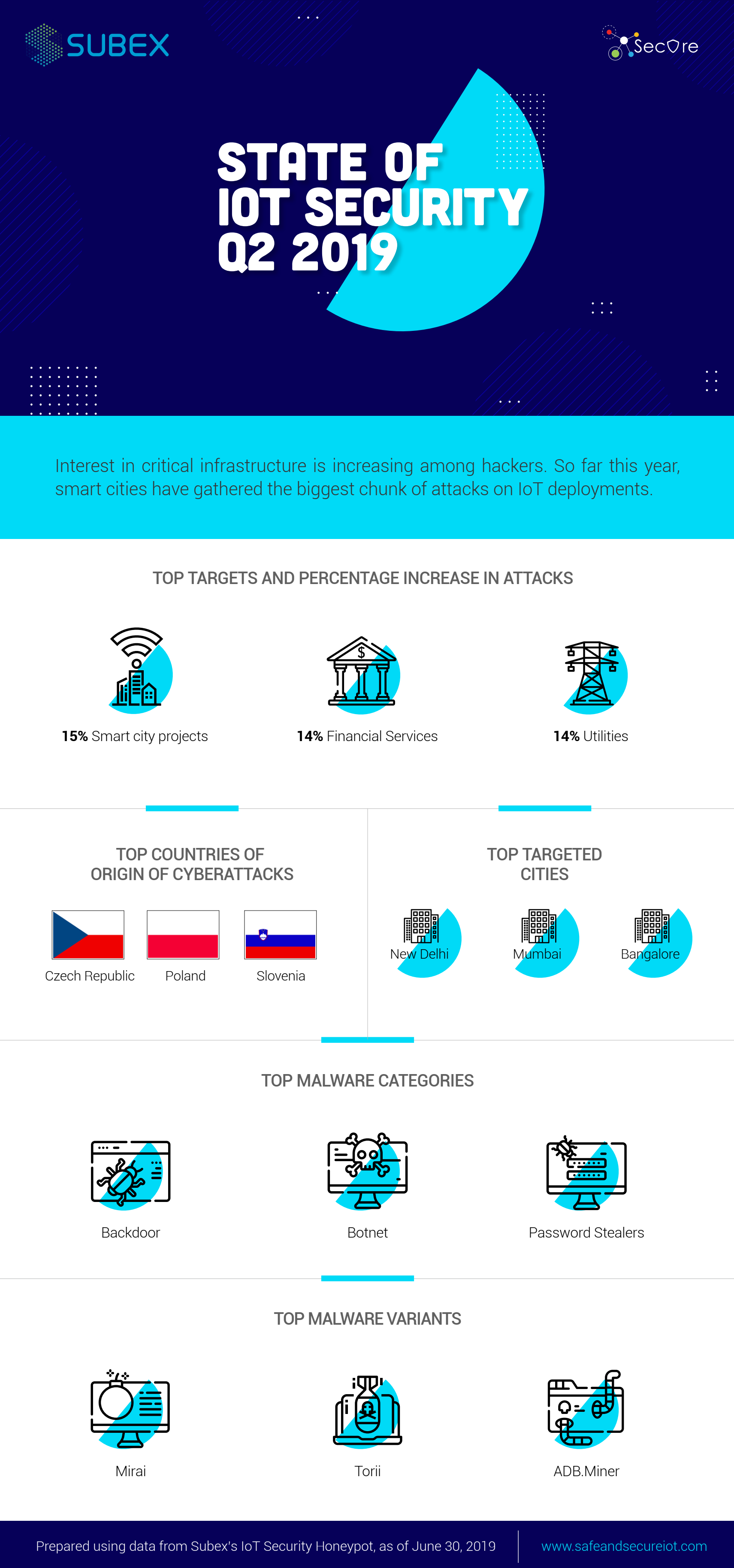

With the IoT taking over the lives, automation has made lives simpler and homes smarter. Smart homes are the base of smart cities and à more efficient lifestyle. Connected home technology is designed to automate functions and bring to individuals control over their property.

Smart homes make lifestyle easy with its smart features like

- Easy to install

- Easy on pocket

- Easy to Operate

- Converts houses into smart home without disruption of existing wiring

- Allows connectivity through 4 interfaces – Voice, App, Remote and the existing switches work too

- 24*7 helpline to help troubleshoot issues

- Easy to buy, through an online eShop

- Can be customized to individual needs

Schneider Electric’s Easy Homes is for every home – existing, old, and new.

A number of questions about efficient handling of voltage fluctuations, wiring, AMC and durability, and more were patiently answered by the Schneider Electric team.

Easy Homes – Pricing

Starting at Rs. 28,998, Easy Homes is affordable and can be installed without changing the existing electrical setup, upgrading homes in just about four hours. Further, in case of any challenges, a local electrician is available 24*7 to troubleshoot the device, thereby easing the overall maintenance process.

Easy Homes – Where to Buy

It is easy to buy Easy Homes from Schneider Electric and one can purchase the product in just three simple steps on the website.

Wrapping it up

There are already a number of devices like smart bulbs, smart fans, etc. available in the market which are preferred by DIY [Do It Yourself] enthusiasts. However, there is no single-point contact to isolate & solve problems in case the device falters or stops working. The advantage of Easy Homes is that it comes from a reputed brand like Schneider and their platform acts as a single-point contact for all your smart home needs.

Easy Homes addresses to the entire spectrum of consumers who aim to convert their normal homes into smart-homes without much hassles or getting into the technicalities of the technology.

The report was released by Minister of State for Home, Krishna Reddy at a function in New Delhi.

The report was released by Minister of State for Home, Krishna Reddy at a function in New Delhi.